Why air curtains can improve your cold store’s efficiency

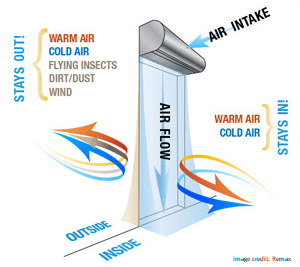

In any industry, but especially in cold storage or refrigerated logistics, small ‘one percenter’ efficiency gains can lead to significant profit and productivity gains over the long term. Air curtain systems blow chilled air over doorways to provide a seal between the varying temperatures on each side of the door in a cold store. The effective installation of these systems could help you and your company save energy, improve productivity, reduce hazards and improve hygiene. Air curtains are a ‘one percenter’ that can pay serious dividends to your team’s productivity and profitability in the long run!

Air curtains can…

1. Save you energy and bottom line

In a traditional cold store with no air curtain, temperatures in the door’s surrounding area can increase by 4 – 10°C every time the door is opened. This means the cooling systems have to expend more energy to regulate the temperature, leading to higher costs as more energy is consumed and an increased carbon footprint for the company.

The installation of an air curtain can reduce this temperature variation by up to 90%, down to less than a degree! This regulates the temperatures better which translates into energy savings and lower costs. Furthermore, the actual lifetime of the equipment will be optimized as their work load is reduced.

2. Improve the cold store’s productivity

Air curtains allow cold stores to leave their doors open all the time while in operation, allowing vehicles and personnel to move around more easily and efficiently. The wear and tear on plastic slats and roller doors means air curtains will generally have less repairs down time, leading to superior productivity. Furthermore, by reducing the ‘hot spots’ around doorways product spoilage on pallets near the doors can be minimised and the usable space in the warehouse increased. So, they reap productivity gains all around!

3. Remove unnecessary WHS hazards

Switching your cold store to air curtains can reduce multiple unnecessary hazards. By removing plastic slats or roller doors visibility is improved which reduces the risk of collisions or accidents. The misting and icy build ups caused by warm air flooding into a freezer is removed, both of which pose hazards for pedestrians & forklifts. Obviously, these improvements also lead to productivity gains, as lost time incidents (LTIs) are reduced.

4. Optimize product quality and hygiene

The hygiene of your cold store can also be optimized through the use of air curtains. As we’ve already mentioned, the reduction of ‘hot spots’ will improve quality control and product spoilage as food temperatures aren’t compromised. The continual rushing of cold air will also discourage pests such as insects or rodents from entering and will effectively keep particles and fumes such as dust or smoke out. Again, these improvements will translate into productivity and profits gains for the company.

In conclusion, an effectively installed air curtain is an investment can that reap extensive profit and productivity gains for any company with a cold store. Energy can be saved, productivity improved, WHS hazards reduced and product quality and hygiene maximised!