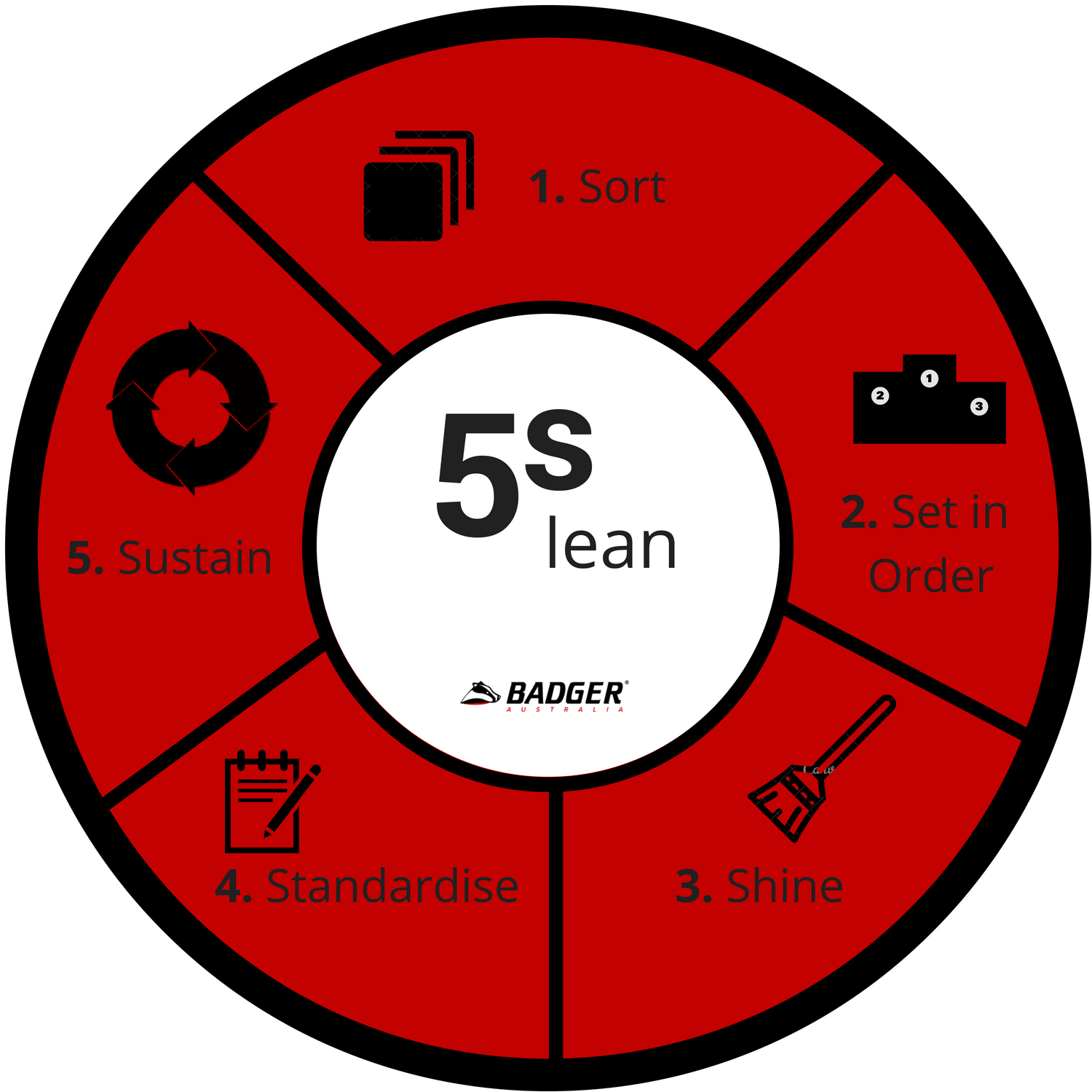

Learn 5S Lean in 2 Minutes

Lean is a phenomenally large topic that can be very daunting and time consuming to get your head around. This post will give you a very general, brief overview of one of the most important Lean principles; the 5 Steps of Lean, or 5S principles.

The post will not answer all your Lean questions, rather it will ‘set you on your way’ in researching and living Lean, as it is a lifelong learning pathway, not something you can pick up ‘overnight’.

A 2 MINUTE WRAP ON 5S LEAN

1. Sort

1. Sort

The first ‘S’ is Sort which focuses on eliminating unnecessary or unneeded items in the workplace such as old tools, supplies or equipment. This step leads to your company maximising space and uncluttering the workplace.

2. Set in Order

The second ‘S’ is Set in Order which involves the initial process of arranging each work area for convenience and efficiency to maximise productivity. The process should focus on minimising or eliminating tasks that don’t add value such as reaching, bending and stretching.

3. Shine

The third ‘S’, Shine, requires your staff to clean and tidy the work place after EVERY shift. By keeping the area visually clear, this step allows your company to quickly identify potential issues that could threaten your lean processes in the long term.

4. Standardise

‘S’ number four involves standardising the successful improvements you make to your processes in the first three steps by documenting them and making the documentation, whether it be posters or booklet, readily available.

5. Sustain

The fifth ‘S’ is the hardest of all; maintaining all the steps on a daily basis to ensure the improvements you make don’t ‘drop off’ as time goes on. This step involves what is known as ‘sharpening the saw’; keeping practice of the steps sharp and disciplined.